Authorized Distributors

Suppliers

About Us

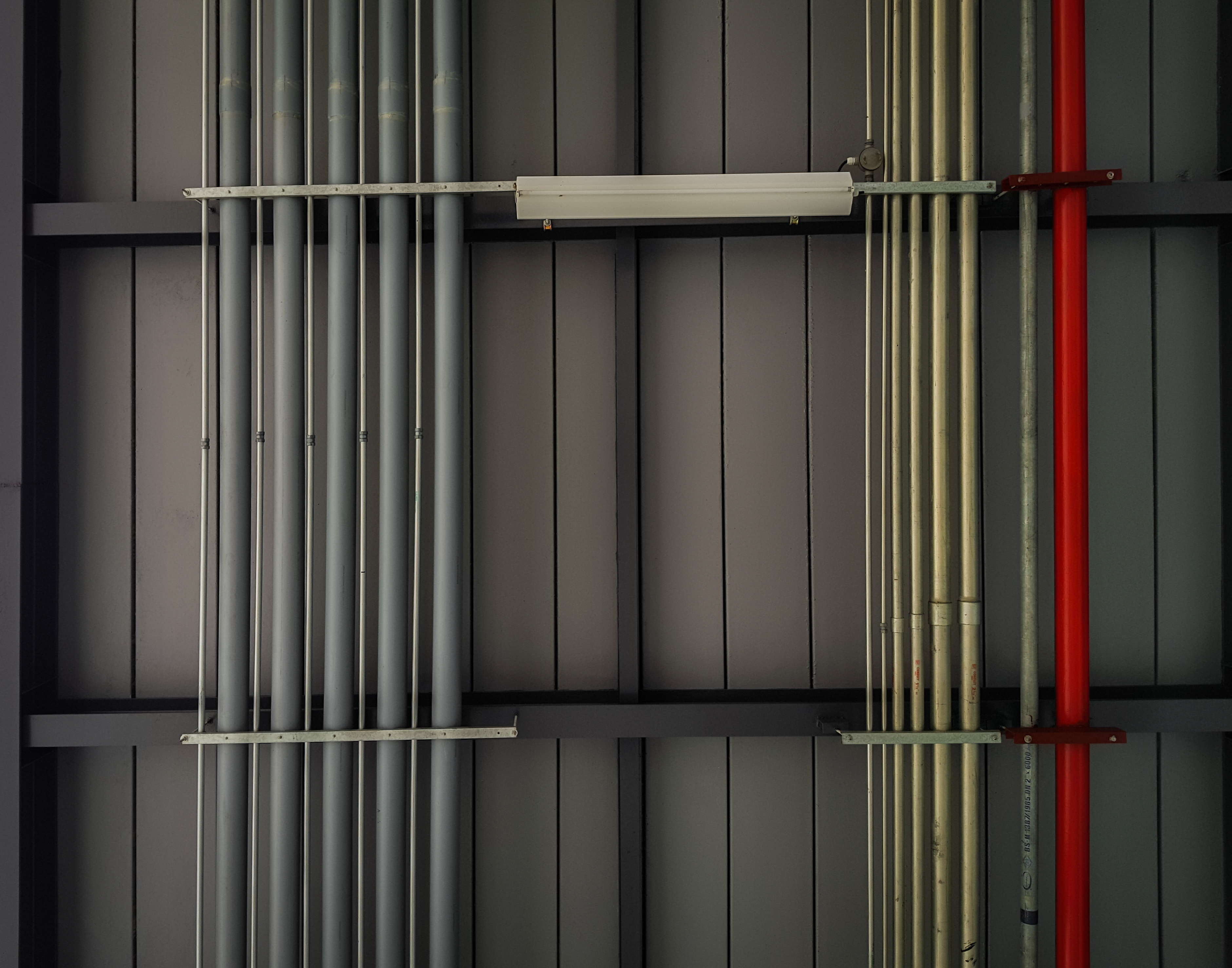

Reputed & Trusted Suppliers of Steel Pipes & Tubes

At Shubham Pipes & Tubes (India), we are committed to ensuring that the pipes/ tubes adhere to the Indian & International specifications and we are highly focused on delivering superior quality materials from the most reputed manufacturers

Projects Supplied with

Happy Clients

Years of Experience

MT Annual Lifting

Company Details

With over 25+ years of experience in the Steel Pipe industry,

Shubham Pipes & Tubes (India) was established to streamline and simplify the procurement process of Pipes, Fittings & Structures for our clients. With our extensive network of manufacturers, stockists, traders & logistics partners, we ensure timely delivery along with the best prices.

Along with the supply of materials, we also have a deep understanding of the day-to-day operational hassles and we assist our clients with:

- Third Party Inspection (TPI) as per end-user requirement

- FOR rates from our trusted logistics partners

- Pipes availability in various grades, thickness & sizes

- Liaising with multiple stakeholders to ensure timely dispatch

- Internal/ External Coating or Varnishing of Pipes

Our Services

Explore the premium solutions we offer to elevate your property journey.

Our Products

Trusted by thousands in the pipe industry.

Industries

Trusted by thousands in the pipe industry.